Local Cane Factory

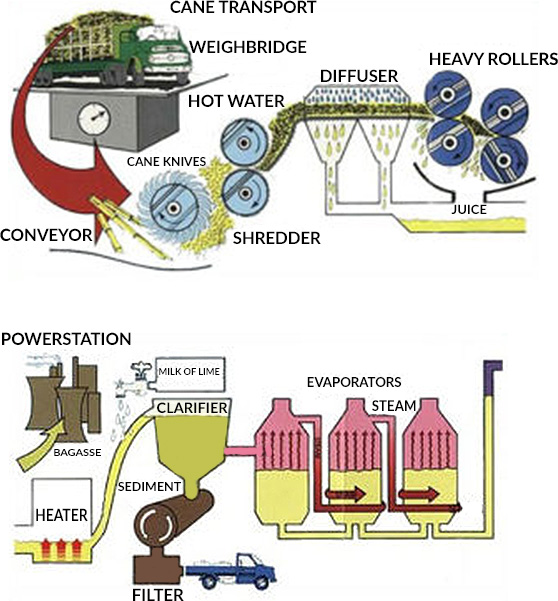

Once cut, the cane is delivered straight to the factory since after burning off and cutting the sugar content deteriorates very rapidly. At the factory :

- The cane is cut into small pieces and shredded.

- It is crushed between heavy rollers to dewater the fibre.

- Juice is extracted in a perculation process with water in the diffuser.

- Lime is added to clean the resulting juice.

- The brown liquid is clarified to remove fibre particles and other impurities.

- Then the juice is boiled under vacuum to form a thick syrup.

- The syrup is then seeded to grow sugar crystals.

- The crystals (raw sugar) and syrup (molasses) are separated in a centrifuge (like a giant spin dryer).

- Brown raw sugar crystals are produced containing up to 4% of raw sugar impurities.

By Products

The by-products from the sugar production process, namely bagasse or cane fibre and molasses do not go to waste, but are utilised for a number of purposes. The bagasse is used in boilers of the power stations at the mills to generate electricity. Bagasse is also the basic ingredient of a range of fibre boards.

RCL Foods Sugar and Milling (Pty) Ltd − Sugar Animal Feed division, MOLATEK, uses a combination of bagasse, molasses and other ingredients to produce a full range of animal feeds at MOLATEK’s Malelane factory.

The other by-product, cane molasses, is also converted into rum and baker’s yeast as well as into animal feed and industrial potable alcohol.